Dodge Ram Fuel Fill Problems: A Comprehensive Guide

Dodge Ram trucks are widely appreciated for their power and reliability, but a recurring issue with fuel fill problems has left many owners frustrated. Common complaints include the fuel pump shutting off prematurely, difficulty filling the tank, and even fuel spilling onto the ground. These problems often stem from issues like a faulty fuel filler neck, a malfunctioning rollover valve, or blocked vent tubes within the EVAP system.

In colder climates, the situation worsens due to reduced flexibility of components, exacerbating venting issues. While some have found temporary fixes like adjusting the nozzle position, most owners report that permanent solutions often involve replacing the filler neck, vent tube, or even the entire gas tank. Despite its prevalence across various Ram models, manufacturers have yet to issue a widespread recall, leaving many to rely on warranties or out-of-pocket repairs.

Common Symptoms of Dodge Ram Fuel Fill Problems

Dodge Ram owners facing fuel fill issues often report a frustrating set of symptoms that disrupt their refueling experience. One of the most common complaints is the fuel pump shutting off prematurely, causing the pump nozzle to click repeatedly even when the tank is far from full. This issue can make filling up a time-consuming and irritating task. In many cases, slow refueling becomes the only workaround, as fuel trickles into the tank despite attempts to adjust the pump nozzle or settings.

Another widespread symptom is gas spillage, where fuel overflows onto the ground during the refueling process. This not only wastes fuel but also creates safety and environmental hazards. Additionally, the impact of colder temperatures exacerbates these issues, as certain components in the fuel system, such as vent tubes or valves, may become less flexible or prone to malfunction in low temperatures. Recognizing these symptoms is the first step toward diagnosing and resolving the root causes of Dodge Ram fuel fill problems.

Causes Behind the Fuel Fill Issues

The root causes of fuel fill problems in Dodge Ram trucks are often linked to design flaws and component malfunctions within the fuel system. A faulty fuel filler neck design is one of the most frequently cited issues. Obstructions or improper venting in the filler neck can restrict airflow, leading to pressure build-up that causes the fuel pump to shut off prematurely.

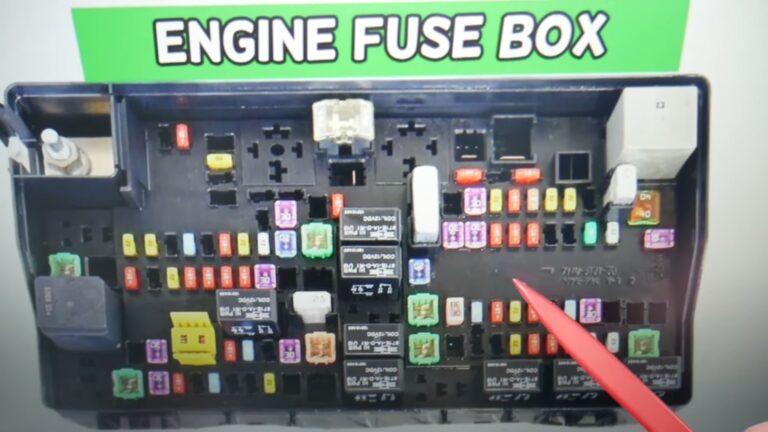

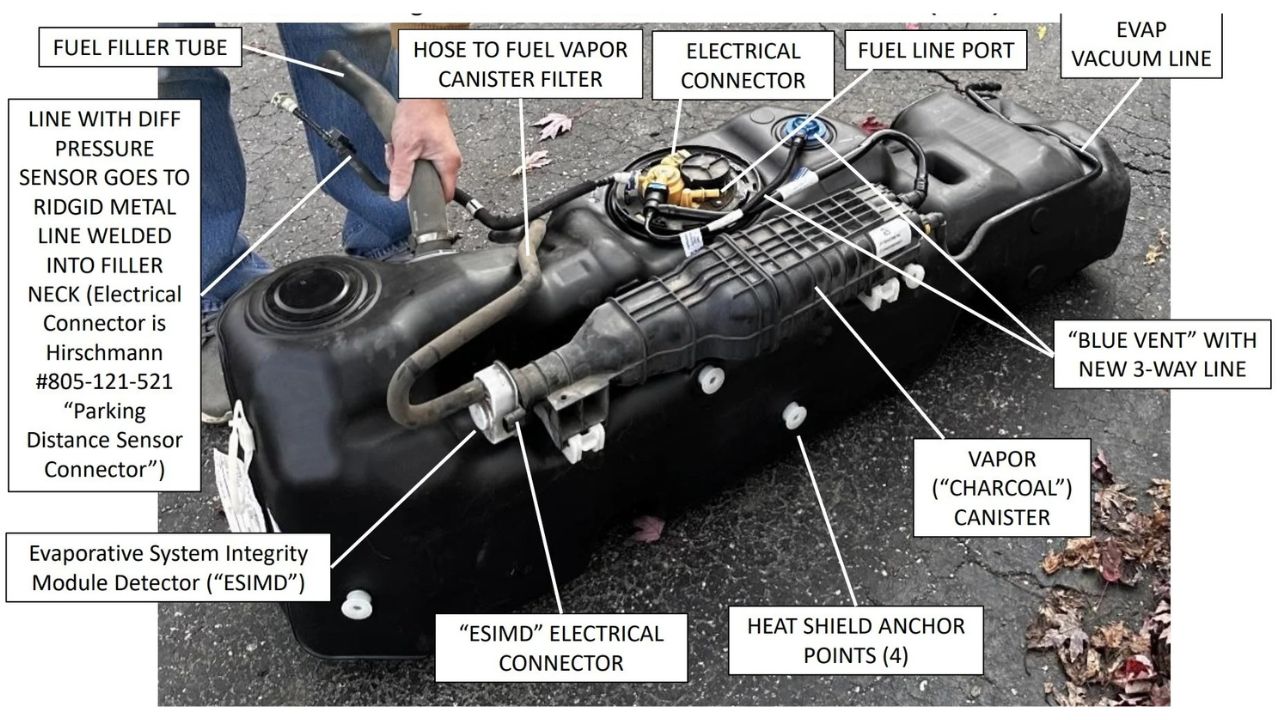

Another common culprit is vent tube blockages, where the tubes responsible for releasing air and vapor during refueling become clogged or damaged. These blockages often involve the charcoal canister, which filters fuel vapors as part of the vehicle’s EVAP system. When clogged, this component fails to release the pressure required for smooth refueling.

A malfunctioning rollover valve is another key issue. This valve, located at the entrance of the gas tank, is designed to prevent fuel from spilling in the event of a vehicle rollover. However, if it becomes stuck or misaligned, it can restrict fuel flow during refueling. Additionally, the newer capless fuel systems on Dodge Rams, while convenient, have been reported to exacerbate these problems by making the fuel system more sensitive to pressure changes and alignment issues.

Also Read: Common Dodge Ram Climate Control Problems

Solutions to Dodge Ram Fuel Fill Problems

Addressing fuel fill issues in Dodge Ram trucks requires targeted solutions based on the underlying cause. Here are the most effective and commonly recommended fixes:

1. Replace the Fuel Filler Neck

A redesigned fuel filler neck is often the first step in resolving refueling problems. Newer versions of this component address venting issues by improving airflow, allowing fuel to flow smoothly into the tank. Owners should ensure the replacement part is the updated design recommended by Dodge.

2. Clear or Replace the Vent Tube

Clogged vent tubes are a frequent cause of pressure build-up during refueling. These tubes can be cleared by mechanics using specialized tools to remove obstructions or replaced entirely if damage is extensive. This ensures proper airflow during refueling and prevents premature shutoff.

3. Inspect and Replace the Rollover Valve

The rollover valve at the base of the fuel filler neck may stick in a closed position, restricting fuel flow. Mechanics can assess whether the valve is operational or replace it if necessary. In severe cases, a full gas tank replacement may be needed, as the valve is often integrated into the tank assembly.

4. Replace the Charcoal Canister

If blockages in the EVAP system are causing venting problems, replacing the charcoal canister can restore proper pressure regulation. This is particularly important if the canister is clogged with fuel residue or has become saturated over time.

5. Consider a Gas Tank Replacement

In cases where the fuel tank itself is defective—such as when internal components like check valves are permanently stuck—a complete tank replacement is often the only long-term solution. Ensure that the replacement tank features updated designs to avoid repeating the issue.